Screen Flip Component Settings Panel

容器ID名称:#c_grid-1725600294587

关闭翻屏分辨率:768

组件说明:

Please use the module to make the content of each screen, and place the module in the grid container. This screen-turning component can automatically identify the screen-turning content only by setting the grid container ID and the tail screen ID.

The height of the tail screen will be automatically identified to achieve a half-screen flip effect without setting other content.

Noun description:

Container ID:The ID of the raster container in which the content is flipped.

Tail ID:The last one is not full-screen module ID. After setting, it will be automatically recognized and the half-screen flip effect will be realized.

Turn off Flip Resolution:When it is less than a certain resolution width, the screen turning effect is invalid and changed to the sliding screen effect.

Please also note:

Please do not modify and delete the contents of this component to avoid affecting the effect. This component is visible in the maker. The page in the page preview will not be visible.

If you are already familiar with the use of this component, or have completed the production, please remove the rich text element of this screen-turning component.

About

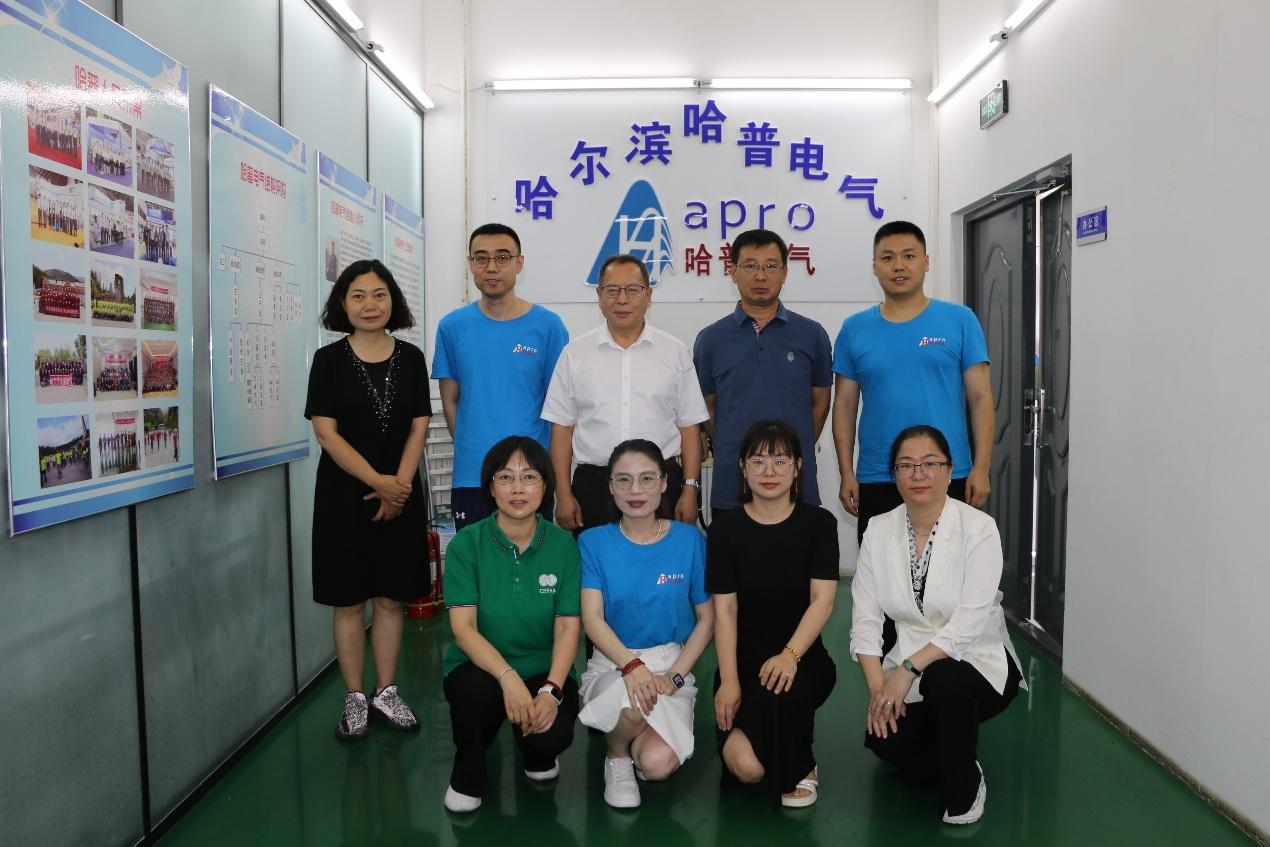

Harbin Hapro Electrical Technology Co. Ltd

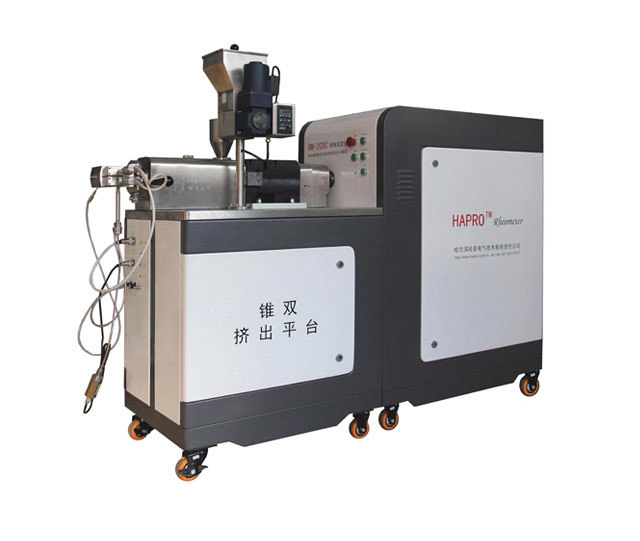

Harbin Hapro Electrical Technology Co. Ltd was founded in 2005. It is the first state level, high-tech enterprise in the National Science Park of Harbin University of Technology. It mainly develops and produces polymer laboratory equipment including melt rheometers, single and twin-screw extruders, plus specialist equipment for the testing and manufacture of high-tech wire and cables.

Products

OUR PRODUCTS

The Single Screw Extrusion Unit

The Parallel CO-rotating Twin-Screw Extrusion unit

network

Products sold at home and abroad

The product footprint covers the domestic north and south, including Hong Kong, Taiwan and other regions. The international market covers Russia, Belarus, Ukraine, the United States, Germany, Canada, Australia, Italy, Hungary, South Africa, Panama, Mexico, Argentina, Brazil, Chile, Colombia, Egypt, Saudi Arabia, Turkey, the Philippines, India, Iran, Malaysia, Thailand, Singapore, South Korea, Japan, Vietnam and more than 20 countries.

COOPERATE CUSTOMERS

Science and technology research and development personnel

R & D Subsidiary

R&D

Production R & D

R & D cooperation

The company currently has 43 employees, including 1 with a doctoral degree, 6 with a postgraduate degree, 15 with a bachelor's degree, and 21 with a college degree or above.

R & D strength

The company has more than 20 sets of processing equipment such as turning, milling, boring, grinding, drilling, electric spark, wire cutting, polishing, etc., and has now realized the complete numerical control processing of main and precision parts.

Has been granted invention patent

Existing Employees

utility model patent

Currently in the patent application

COOPERATE

COOPERATE CUSTOMERS

CONTACT

Contact Us

Telephone

Summer Sun:+86-18145680702

Haowei Zhang:+86-18845121812

Address

NO.10,12th Hanan Road, Pingfang District, Harbin,China

E-mail: hrbhapro@vip.163.com

Hapro US Office: Maria@hapro-usa.com

Hapro UK Office: Sales@hapro-uk.com

Hapro India Office: manoj@hapro-india.com